In the face of mounting need, UCI Beall Applied Innovation coordinated an ambitious, interdisciplinary effort to design and produce thousands of face shields for UCI Medical Center.

Carolyn Stephens, managing director of enterprise collaborations at UCI Beall Applied Innovation, assembled a team including collaborators from the medical center, the business community, Applied Innovation, UCI School of Medicine, the Sue & Bill Gross School of Nursing, the Henry Samueli School of Engineering and the Claire Trevor School of the Arts (CTSA).

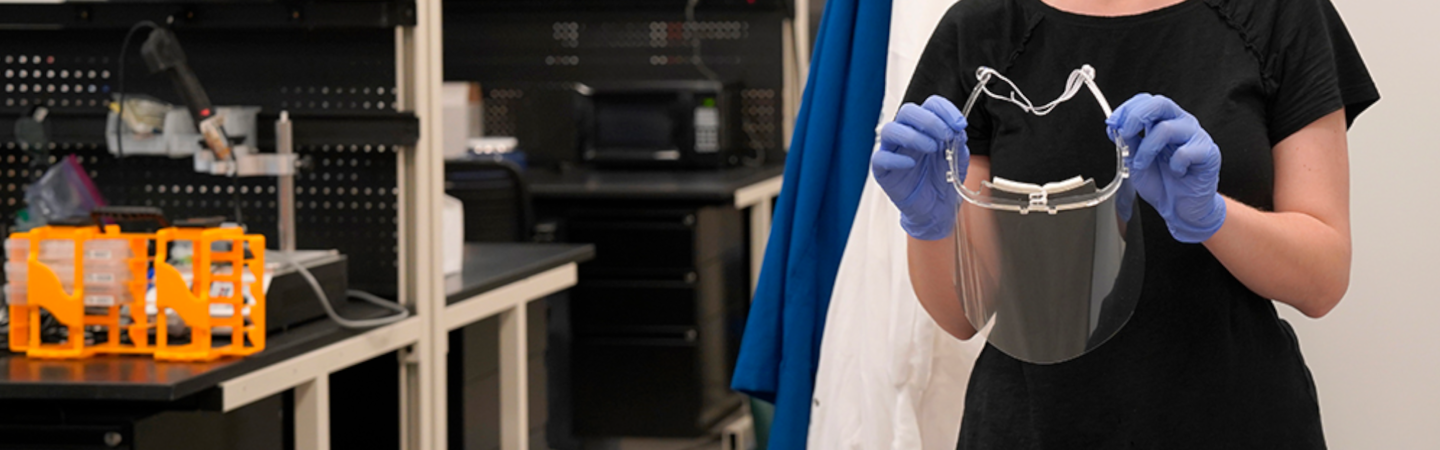

Industry partners consulted on the product’s design, assembly and packaging constraints to ensure they would arrive uncontaminated and in accordance with the medical center’s procurement standards. Jesse Jackson of CTSA and Ben Dolan of UCI’s Institute of Design and Manufacturing Innovation, and their team, created numerous disposable face shield prototypes with laser cutters and 3D printers.

Following feedback on function and desired features from medical professionals, the team quickly mobilized to begin production at the Cove @ UCI, Applied Innovation’s headquarters located at the UCI Research Park in Irvine, CA. Cove lab tenants and UCI students, faculty and staff assembled to produce the single-use face shields, all while employing safe practices and social distancing.

The face shield production is just one way that Beall Applied Innovation has leveraged its resources and connections across industry and business to be a center of COVID-19 innovation. These partnerships shrink traditional production timelines, accelerating the process of going from idea to product launch.

Read the full story on face shield production here: